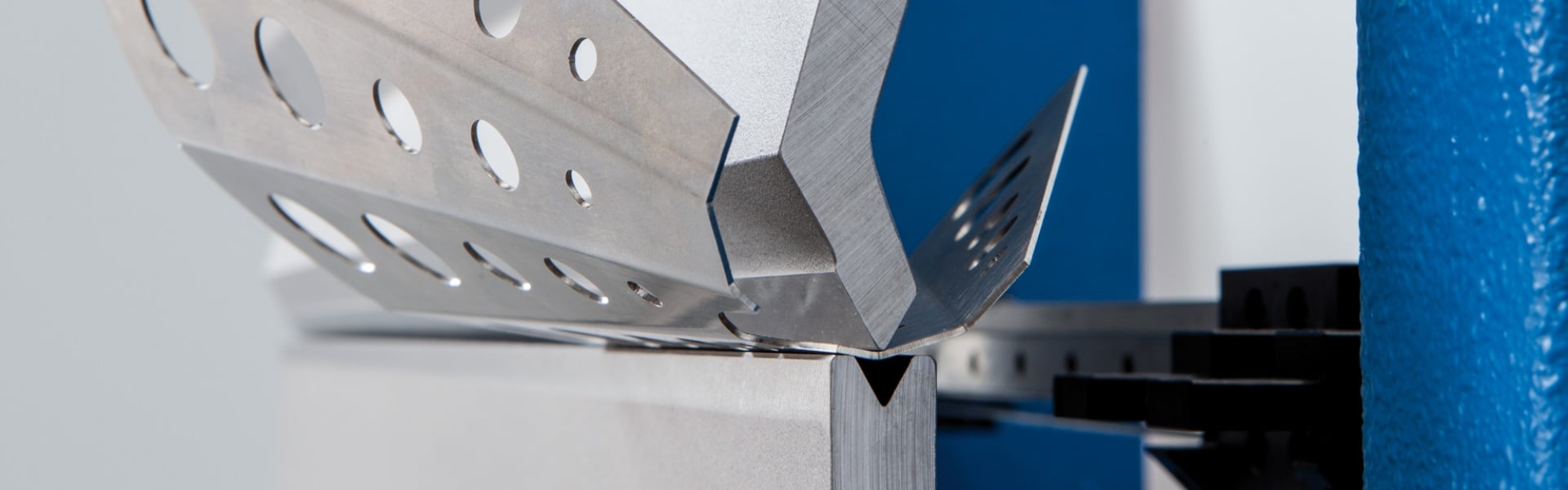

Plegadoras

Plegadoras eléctricas, robotizadas y para remates. Descubre la excelencia en la deformación de chapa con nuestra amplia gama de máquinas plegadoras.

Plegadoras eléctricas, robotizadas y para remates. Descubre la excelencia en la deformación de chapa con nuestra amplia gama de máquinas plegadoras.

Máquinas diseñadas para el corte de la chapa. Gama de máquinas punzonadoras de gran rendimiento y alta productividad con bajos costes de gestión.

Corte de esquinas con regulación automática de las cuchillas.

Aplanado para un acabado excelente de las piezas metálicas. Las máquinas aplanadoras facilitan los procesos posteriores y favorecen a un aumento considerable de la productividad.

Máquinas para diseñadas para el corte de la chapa.

Cizallas para chapa robusta, rápidas y de gran precisión.

Punzonadoras y plegadoras para pletina de cobre.

Rectificadoras para el mantenimiento del utillaje.

Cuello de cisne y doble montante.

Gran capacidad de espesor y profundidad de plegado.

Desbarbado, redondeo de aristas, acabado superficial y eliminación del óxido lateral.

Optimización del espacio, seguridad y reducción de costes.

Consulte nuestra gama de utillaje de punzonado y plegado, la máxima calidad y precio más competitivo del mercado.

Lantek es una marca española globalmente reconocida por ofrecer la solución perfecta para la industria del metal independientemente del sector de la empresa.

Nuestra maquinaria de segunda mano.